Tell us what your work consists of!

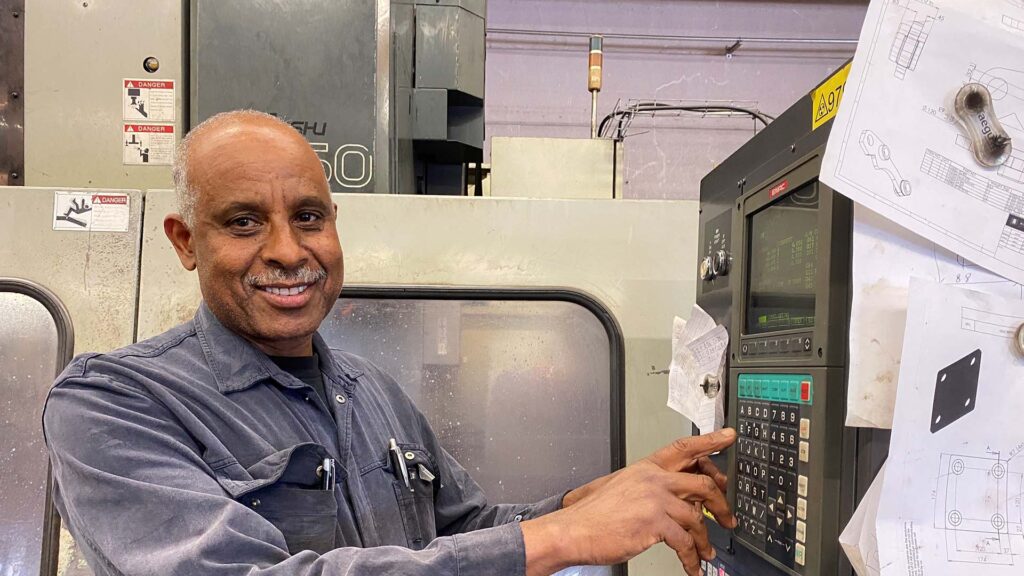

– My job consists of providing my colleagues with bent and cut details. I do that with the help of the plasma cutter and the press brake.

What is important in your job?

– It is good data knowledge and a good eye for how the programs for the plasma cutter and the press brake should be designed. It is important that what I produce is of the right quality so that the job becomes easier for those who then build and weld the products together.

What do you think is the most fun about your work?

– Much of what we manufacture are different products. This means that the work is varied, challenging and always feels like something new. I like when the work flows, is problem-free and that material comes and leaves me continuously.

Which of all the products do you like the most?

– It is the high tipping bucket from Ufo because it contains many bent parts that must fit together.

Why choose Fronteq as a work tool supplier?

– This is because we have a wide range of tools and that the products can be adapted as needed. We have high quality and good delivery reliability.

What do you prefer to relax with when you are off duty?

– Then I fish for salmon or trout in Lake Vänern. I also like to move around in nature at Kinnekulle.